|

Back to Rocket Manual

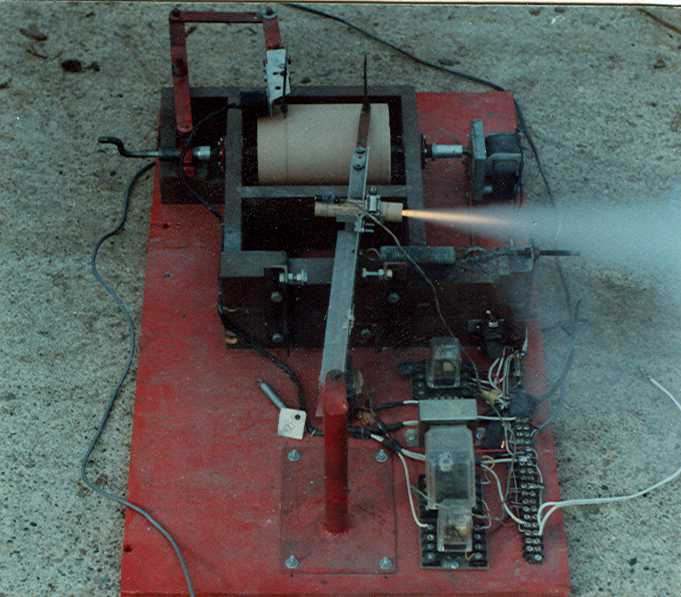

This is the

same picture used in the brochure.

What it does

This machine, though

looking crude, actually does a lot and does it accurately. Here is

what it does:

-

Ignites the engine remotely

-

Draws a thrust-time curve

-

Records the time delay for the ejection

charge

-

Works with all sizes of engines

How it works

The engine is mounted

on a rigid arm that pivots around an axis on one end. A calibrated

spring is attached to the arm. When the engine fires-it moves the arm

a distance proportional to the thrust developed. At the end of the arm

is a weighted ink pen that writes on a strip of paper wrapped around a drum.

The drum rotates at a specific speed so the thrust is recorded as the drum

moves and the result is a thrust time curve. The arm is long compared

to the arc it moves in so the error due to moving in an arc rather than a

straight line is minimal. The mass of the arm is also very low

compared to the engine force so that error is also minimal. The motor

that drives the recording drum is automatically started at the same time as

the electrical ignition for the engine.

In addition, another pen scribes a line below

the thrust time curve. This pen is driven off a screw on the same axle

as the drum and so moves a small amount across the drum as the drum rotates.

This way, it doesn't overlap itself as the drum makes multiple revolutions.

This is so that a delay can be recorded that lasts more than one revolution.

A small photo sensor is mounted on the forward end of the engine and detects

the flash of the ejection charge. This triggers a solenoid that causes

this second pen to move and so records the time of the ejection charge

relative to the main thrust time curve. The crank is so that the coupling

to the drum can be loosened and the screw can be backed up easily to the

starting point for the next test.

Different size engines can be tested from the

tiniest 0.25" ID to the largest 1.25" ID. A number of different

springs were used and each one was calibrated. The stationary end of

the spring was attached to an eye bolt which could be easily and quickly

changed for different lengths of springs so all charts were made from zero

force.

Construction.

The construction can be seen fairly well from

the picture. All components were easily obtainable and were made with

nothing more than standard hand tools, a table saw, drill press, and a gas

welder (used to braze a few parts). The drum was a piece of PVC pipe,

probably about 3" sched. 40. Wooden circles were cut and sanded to fit

the two ends and a 1/8" steel shaft was run through it. An old

ErectorSet part was used to fix the shaft to the wooden end. The drum

motor I think was ordered from Graingers. It was a 115V AC gear-reduced

motor that only turned about 1.5 RPM. I was thinking it was a BBQ

rotisserie motor but from looking at the picture, apparently not.

The photo sensor, relays, amplifier for the

photo sensor and transformer (115V to 12V for igniter) were ordered from

Graingers. The solenoid was out of a 12V solenoid operated water valve.

The arm was aluminum angle and on the end was attached a piece of hack saw

blade. This acted as a spring and supplied the pressure to make the

ink pen write. All the other pieces were just wood, steel plate, steel

rounds, and steel flats.

Hundreds of engines were tested on this

machine. Unfortunately, I didn't keep any of the charts but a few were

reproduced for the manual and brochure.

Back to Rocket Manual

|